-

Cetakan komponen mobil

-

Cetakan Bagian Plastik Otomatis

-

Cetakan injeksi otomotif

-

Cetakan Injeksi Tembakan Ganda

-

Cetakan Injeksi Medis

-

Cetakan Injeksi Multi Rongga

-

Cetakan Injeksi Elektronik

-

Cetakan Plastik Suhu Tinggi

-

Cetakan membuka tutup

-

Home Appliance Mould

-

Cetakan gigi

-

Pencetakan Injeksi Overmolding

-

Komponen Cetakan Plastik

-

StefanKami senang telah bekerja sama dengan ERBIWA, dan terima kasih atas dukungan Anda untuk setiap proyek kami.

StefanKami senang telah bekerja sama dengan ERBIWA, dan terima kasih atas dukungan Anda untuk setiap proyek kami. -

RobertSangat menyenangkan untuk menerima cetakan dengan kualitas tinggi dan layanan yang unggul, tetapi harga yang menguntungkan. Kami akan terus bekerja sama dengan Anda dalam proyek-proyek masa depan.

RobertSangat menyenangkan untuk menerima cetakan dengan kualitas tinggi dan layanan yang unggul, tetapi harga yang menguntungkan. Kami akan terus bekerja sama dengan Anda dalam proyek-proyek masa depan. -

CarlosAnda adalah tim yang dinamis dan kuat, saya telah melihat masa depan manufaktur Cina dari Anda semua.

CarlosAnda adalah tim yang dinamis dan kuat, saya telah melihat masa depan manufaktur Cina dari Anda semua.

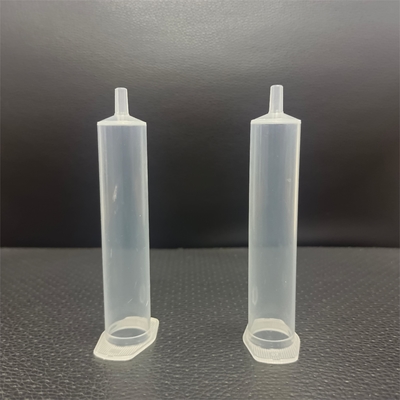

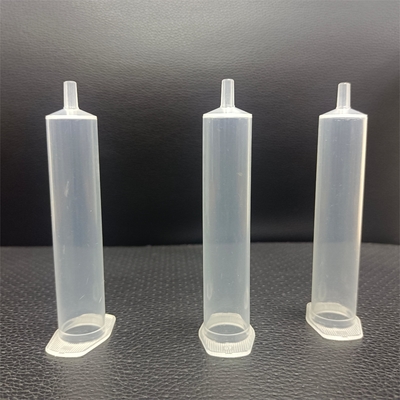

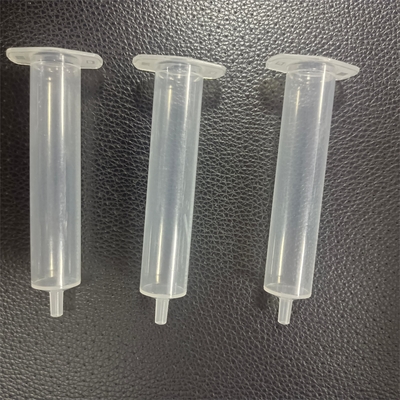

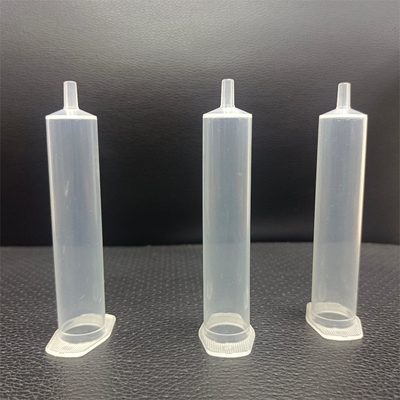

ERBIWA Mould - Medical Grade High Precision P20 Steel Disposable Plastic Syringe Injection Mould (Sterile Packaging Comp)

| Tempat asal | Guangdong, Cina |

|---|---|

| Nama merek | Erbiwa Mould |

| Sertifikasi | ISO 9001: 2015 IATF 16949: 2016 |

| Nomor model | Disesuaikan |

| Kuantitas min Order | 1 set |

| Harga | negotiable |

| Kemasan rincian | paket standar ekspor |

| Waktu pengiriman | 30-60 hari |

| Syarat-syarat pembayaran | TT, L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Menyediakan kemampuan | 1 Set Per Bulan |

| Kontrol Kualitas | Diperiksa dan Dikonfirmasi Ulang Sebelum Pengiriman | Pelari cetakan | Pelari dingin dan pelari panas |

|---|---|---|---|

| Bahan Baku Produksi Plastik | PP, PA6, PLA, ABS, PE, PC, POM, PVC, PET, PS, TPE/TPR, dll. | Nama produk | Cetakan Suku Cadang Mobil Kelas Profesional untuk Komponen Otomotif Unggul |

| Fitur | Menarik Dan Tahan Lama | Produksi Bulan | 50 set per bulan |

| Menyoroti | Cetakan injeksi suntik plastik sekali pakai |

||

ERBIWA Mould - P20 Injeksi Plastik Plastik Satu Kali Penggunaan P20 Pegas Tinggi Kecepatan Medis (Kompatibel dengan Kemasan Steril)

Parameter teknis:

| Parameter teknis | Nilai |

|---|---|

| Pengedar Cetakan | Cold Runner dan Hot Runner |

| Kontrol Kualitas | Diinspeksi dan Dikonfirmasi Lagi Sebelum Pengiriman |

| Kategori produk | Cetakan Bagian Mobil |

| Produksi Bulan | 50 Set Per Bulan |

| Toleransi ukuran | +/- 0,05 mm |

| Bahan baja | 718H, P20, NAK80, S316H, SKD61, dll. |

| Fitur | Menarik dan awet |

| Harga Cetakan | Biaya Efektif dan Kompetitif |

| Layanan Pasca Penjualan | 12 Bulan Gratis |

| Waktu Pengiriman | 30-60 hari |

Produk cetakan suku cadang mobil ini sangat cocok untuk suku cadang mobil berkualitas, suku cadang mobil kustom, dan pembuatan suku cadang mobil.

Fitur Produk

Bahan kelas medis:Mengadopsi baja P20 berkualitas tinggi dengan kekerasan tinggi dan ketahanan korosi untuk memastikan stabilitas jangka panjang dan keselamatan cetakan dalam produksi produk plastik medis.

Proses presisi tinggi:cetakan mengadopsi teknologi pemrosesan CNC canggih, dengan kontrol presisi pada tingkat mikron, memastikan dimensi yang akurat dari berbagai bagian jarum suntik plastik sekali pakai, seperti piston, tong,tutup jarum, dll, untuk memenuhi persyaratan standar tinggi peralatan medis.

Desain Kemasan Aseptik yang Kompatibel:Desain cetakan sepenuhnya mempertimbangkan persyaratan kemasan aseptik jarum suntik, memastikan bahwa produk jadi mudah untuk mengotomatiskan kemasan,mengurangi risiko kontaminasi sekunder, dan memenuhi standar kebersihan yang ketat dari lingkungan rumah sakit dan penggunaan klinis.

Struktur cetakan multi-ruang:struktur cetakan multi-ruang opsional, sangat meningkatkan efisiensi produksi, cocok untuk produksi massal jarum suntik plastik sekali pakai, mengurangi biaya satu bagian.

Kompatibilitas bahan:Cocok untuk berbagai jenis plastik kelas medis, seperti polipropilena (PP), polietilena (PE), dll. untuk memastikan transparansi, kekakuan dan stabilitas kimia jarum suntik,sesuai dengan standar keselamatan bahan untuk perangkat medis.

Sistem pendinginan presisi:Saluran air pendingin yang dioptimalkan yang dibangun di dalamnya memastikan pendinginan cetakan yang cepat, memperpendek siklus produksi dan meningkatkan produktivitas,dengan menjaga stabilitas dimensi komponen jarum suntik.

Skenario yang Bisa Digunakan

Lembaga medis:cocok untuk perlengkapan medis sekali pakai di rumah sakit, klinik, pusat pertolongan pertama dan tempat lainnya.

Vaksinasi:Cocok untuk program vaksinasi skala besar untuk memastikan penggunaan jarum suntik yang aman, steril dan sekali pakai.

Penelitian laboratorium:untuk memenuhi permintaan jarum suntik steril presisi tinggi dalam percobaan penelitian ilmiah.

Dalam bidang manufaktur perangkat medis modern, cetakan injeksi untuk produk medis memainkan peran penting.tetapi juga sangat meningkatkan efisiensi produksi dan efektifitas biayaDari desain hingga produksi, kontrol kualitas siklus penuh cetakan injeksi produk medis adalah kunci untuk mencapai kualitas tinggi dalam perangkat medis.kita akan membahas proses ini secara mendalam, menunjukkan bagaimana langkah-langkah manajemen kualitas yang ketat dapat memastikan bahwa cetakan injeksi medis selalu dalam kondisi optimal.

Tahap awal: desain dan perencanaan

Semua dimulai dengan desain. Perancangan cetakan injeksi medis harus memperhitungkan persyaratan fungsional produk, sifat material dan proses produksi.Tim desain menggunakan perangkat lunak CAD canggih untuk pemodelan 3D untuk memastikan bahwa setiap detail cetakan dengan akurat mencerminkan karakteristik geometris produkSelain itu, sistem pendingin, lokasi gerbang,dan slot ventilasi cetakan juga dievaluasi selama tahap desain untuk memastikan pengisian seragam dan pendinginan cepat dari peleburan plastik selama proses injeksi, dan untuk menghindari cacat seperti gelembung udara dan lubang penyusutan.

Tahap menengah: pembuatan cetakan dan validasi

Pembuatan cetakan adalah proses yang kompleks yang melibatkan teknologi pemesinan presisi tinggi, seperti penggilingan CNC, pemesinan debit listrik (EDM), pemotongan kawat, dan sebagainya.Produsen harus memilih baja cetakan berkualitas tinggi untuk memastikan cetakan memiliki kekerasan yang cukup, ketahanan terhadap keausan dan ketahanan korosi untuk mengatasi suhu tinggi dan tekanan tinggi dampak dari peleburan plastik selama produksi jangka panjang.serangkaian tes, termasuk cetakan uji, dilakukan untuk memverifikasi kinerja cetakan dan kualitas produk yang terbentuk.Kontrol kualitas pada tahap ini berfokus pada memastikan akurasi dimensi dan permukaan akhir cetakan, serta akurasi geometri dan kualitas penampilan produk.

Tahap akhir: Produksi dan Pemantauan Kontinyu

Ketika cetakan memasuki tahap produksi, pentingnya kontrol kualitas siklus penuh menjadi lebih jelas.seperti instrumen pengukuran optik dan sistem inspeksi sinar-X, untuk memantau dimensi dan struktur internal produk secara real time dan memastikan bahwa setiap komponen memenuhi standar yang ketat.seperti tekanan injeksi, suhu, waktu siklus, dll, juga perlu diatur dengan tepat untuk menjaga stabilitas dan konsistensi kualitas produk.

Peningkatan terus menerus dan umpan balik

Pengendalian kualitas bukanlah tugas satu kali, tetapi proses berkelanjutan di seluruh siklus produksi.Produsen cetakan injeksi produk medis perlu membangun mekanisme umpan balik yang komprehensif untuk mengumpulkan data produksi secara teratur, menganalisis keausan cetakan dan tingkat kegagalan produk, melakukan penyesuaian tepat waktu pada parameter proses,dan bahkan melakukan perawatan dan perbaikan cetakan yang diperlukanSikap perbaikan terus-menerus ini akan membantu memperpanjang umur kerja cetakan dan mengurangi limbah produksi, sambil terus meningkatkan kualitas produk medis.

Kesimpulan

Kontrol kualitas siklus penuh cetakan injeksi untuk produk medis adalah cerminan dari upaya keunggulan dalam industri manufaktur perangkat medis.untuk manufaktur halus, untuk efisiensi produksi yang tinggi, masing-masing tautan tidak dapat dipisahkan dari manajemen kualitas yang ketat.Hanya dengan cara ini kita dapat memastikan bahwa produk medis aman dan dapat diandalkan dalam aplikasi klinis dan membawa manfaat kesehatan nyata bagi pasienDengan kemajuan terus-menerus ilmu kedokteran dan teknologi,proses manufaktur dan strategi kontrol kualitas cetakan injeksi produk medis akan membawa inovasi dan tantangan lebih di masa depan, dan memberikan kontribusi yang lebih besar untuk kesehatan manusia.

![]()

![]()

![]()

![]()

![]()

![]()